KTP Vibro-Insulators® Tapered Hole Plugs and Stoppers:

Karman Rubber KTP tapered plugs cover and seal holes in a variety of applications.

Features and Benefits:

- Tapered to fit various size openings.

- 4 sizes with through holes allowing for the insertion of pipettes or tubing.

- 3 sizes with no through (Solid) holes.

- Available in 50 Durometer Shore A Neoprene, Natural Rubber, EPDM, and Nitrile (Buna-N).

- Temperatures ranges from -40º F to 300º F.

- Other Durometers available upon request.

Applications:

- Water tight applications for plugging or sealing.

- Mitigates cement displacement in the construction industry.

- Oil water and gas drilling.

- Chemical industry.

Environmental Data:

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Neoprene (CR)

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N)

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 8 to 10 weeks.

1.50 |

2.25 |

2.00 |

.375 |

4.25 |

70 |

Natural Rubber |

|||

1.50 |

2.25 |

2.00 |

.375 |

4.25 |

70 |

Neoprene |

|||

1.50 |

2.25 |

2.00 |

.375 |

4.25 |

70 |

Nitrile |

|||

1.50 |

2.20 |

3.04 |

.375 |

5.20 |

70 |

Natural Rubber |

|||

1.50 |

2.20 |

3.04 |

.375 |

5.20 |

70 |

Neoprene |

|||

1.50 |

2.20 |

3.04 |

.375 |

5.20 |

70 |

Nitrile |

|||

1.75 |

3.00 |

4.00 |

.375 |

10.20 |

70 |

Natural Rubber |

|||

1.75 |

3.00 |

4.00 |

.375 |

10.20 |

70 |

Neoprene |

|||

1.75 |

3.00 |

4.00 |

.375 |

10.20 |

70 |

Nitrile |

|||

1.75 |

3.25 |

4.00 |

.500 |

12.50 |

70 |

Natural Rubber |

|||

1.75 |

3.25 |

4.00 |

.500 |

12.50 |

70 |

Neoprene |

|||

1.75 |

3.25 |

4.00 |

.500 |

12.50 |

70 |

Nitrile |

|||

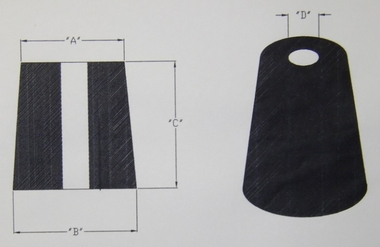

| Small Diameter - in (A) | Large Diameter - in (B) | Height - in (C) | Through Hole - in (D) | Part Weight - oz | Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.