Square Style Vibro-Isolator® Plate Mounts

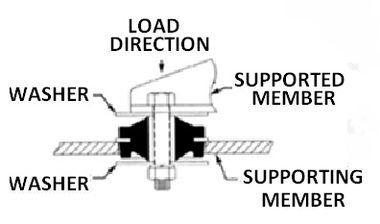

Square Plate Mounts are designed to protect equipment from vibration and noise at low distribuing frequencies. Produced with Natural Rubber these mounts isolate in the horizontal and vertical planes. When used with snubbing washers these mounts offer interlocking metal protection. Plate Mounts are also know as Plateform Mounts.

Features and Benefits:

- Available in two sizes

- easy to install with minimum maintenance

- Available in 40, 50, 60, & 70 Durometer Shore A

- Axial loads from 25 to 480 pounds

- Also available in Neoprene and Nitrile (Buna-N)

- 2-D PDF prints are available for each mount.

- 2-D DWG, 3-D IGES, and 3-D SolidWorks are available upon request

- low profile with interlocking metal protection

- Made in the USA

Applications:

- Small and large compressors, medical equipment, electronic equipment, motors, generators, business machines, panels

Environmental:

- All load ratings are based on using Natural Rubber.

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Delivery is 6 weeks.

2.00 |

2.25 |

1.75 |

.39 |

.196 |

.062 |

.60 |

1.00 |

250 |

.10 |

25 |

40 |

Natural Rubber |

|||

2.00 |

2.25 |

1.75 |

.39 |

.196 |

.062 |

.60 |

1.00 |

325 |

.10 |

32 |

50 |

Natural Rubber |

|||

2.00 |

2.25 |

1.75 |

.39 |

.196 |

.062 |

.60 |

1.00 |

525 |

.10 |

50 |

60 |

Natural Rubber |

|||

2.00 |

2.25 |

1.75 |

.39 |

.196 |

.062 |

.60 |

1.00 |

825 |

.10 |

80 |

70 |

Natural Rubber |

|||

2.88 |

3.25 |

2.56 |

.516 |

.343 |

.125 |

1.38 |

2.00 |

600 |

.25 |

150 |

40 |

Natural Rubber |

|||

2.88 |

3.25 |

2.56 |

.516 |

.343 |

.125 |

1.38 |

2.00 |

1000 |

.25 |

250 |

50 |

Natural Rubber |

|||

2.88 |

3.25 |

2.56 |

.516 |

.343 |

.125 |

1.38 |

2.00 |

1400 |

.25 |

360 |

60 |

Natural Rubber |

|||

2.88 |

3.25 |

2.56 |

.516 |

.343 |

.125 |

1.38 |

2.00 |

1930 |

.25 |

480 |

70 |

Natural Rubber |

|||

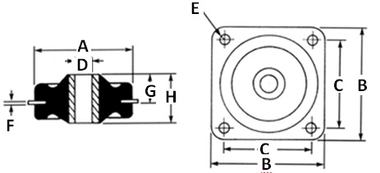

| Height - in (A) | Width - in (B) | Mounting Holes on Center - in (C) | Diameter - in (D) | Mounting Hole Diameter - in (E) | Flange Thickness - in (F) | Radius Required - in (G) | Diameter - in (H) | Axial Spring Rate - lb/in | Axial Maximum Recommended Deflection - in | Axial Load at Maximum Deflection - lb | Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.