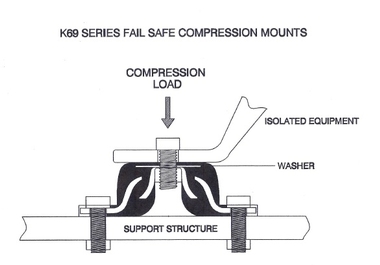

K69 & K695 Series Fail-Safe Vibro-Isolator® Compression Mounts

In addition to the 1st and 2nd generation K69 & K695 Series, Karman Rubber now offers the 3rd generation K69 Series Compression Fail-safe Mounts. The largest selection of compression style fail-safe designed mounts available anywhere.

K69 & K695 Series Features and Benefits:

- Low Cost.

- Ease of installation.

- Rated for higher loads due to the interlocking metal design.

- Seismic rating of 1g (acceleration of gravity).

- Seismic protection in earthquake zones. See below for g-force ratings.

- Available in English and Metric hardware.

- Six sizes with 5 load ranges for each size.

- Static compression loads range from 160 to 750 pounds.

- Fail-safe patented designs with interlocking metals.

- No need for snubbing washers.

- Excellent performance with one, two, three, four and five cylinder engines.

- Suited for both high and Low disturbing frequency applications.

- All directional mounts can be used in shear, tension, and compression applications.

- Suited for low mounting applications.

- The K69 and K695 are the first and second generation series.

- Made in the USA.

K69 and K695 Series Applications:

- Motors, generators, and compressors

- HVAC equipment

- Chemical and food processing equipment

- Centrifuges and pumps

- Highway and off-highway machinery

- Trucks, buses, lifts, and rail transportation

- Marine equipment and ATV's

- Fans, blowers, and portable power equipment

- Seismic protection in earthquake zones.

K69 & K695 Series Material Data:

- The Neoprene elastomer is standard in 30, 40, 50, 60, & 70 Durometer Shore A.

- Operating temperature range (10° F to 180° F).

- Ozone resistant

- Oil, gasoline and solvent resistant.

- Flame resistant

- Structure made of corrosion resistant carbon steel.

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Neoprene (CR)

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N)

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 6 weeks.

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

1600 |

010 |

160 |

30 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

3000 |

.10 |

300 |

40 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

3000 |

.10 |

300 |

30 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

50 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

50 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

60 |

Nitrile |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Nitrile |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Nitrile |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

1600 |

.10 |

160 |

30 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

3000 |

.10 |

300 |

40 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

3000 |

.10 |

300 |

40 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

50 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

50 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

4700 |

.10 |

470 |

50 |

Nitrile |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

6000 |

.10 |

600 |

60 |

Nitrile |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Natural Rubber |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Neoprene |

|||

2.18 |

1.775 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

N/A |

.343 |

7300 |

.10 |

730 |

70 |

Nitrile |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

2100 |

.10 |

210 |

30 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

3700 |

.10 |

370 |

40 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

3700 |

.10 |

370 |

40 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Nitrile |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Nitrile |

|||

2.17 |

1.77 |

3.00 |

3.75 |

3/8-16 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

9400 |

.08 |

750 |

70 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

2100 |

.10 |

210 |

30 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

3700 |

.10 |

370 |

40 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

3700 |

.10 |

370 |

40 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

5200 |

.10 |

520 |

50 |

Nitrile |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Natural Rubber |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Neoprene |

|||

2.17 |

1.770 |

3.00 |

3.75 |

M8X1.25 |

2.27 |

1.12 |

.12 |

.065 |

.343 |

6800 |

.10 |

680 |

60 |

Nitrile |

|||

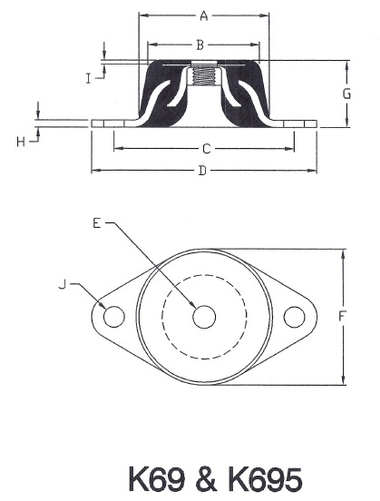

| Mount Diameter - in (A) | Top Diameter - in (B) | Mounting Holes on Center - in (C) | Length - in (D) | Thread Tap or Hole Size (E) | Width - in (F) | Height - in (G) | Flange Thickness - in (H) | Washer Thickness - in (I) | Mounting Holes - in (J) | Compression Spring Rate - lb/in | Compression Maximum Recommended Deflection - in | Compression Load at Maximum Deflection - lb | Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.