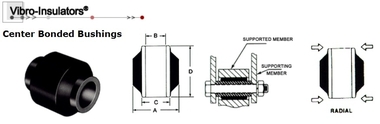

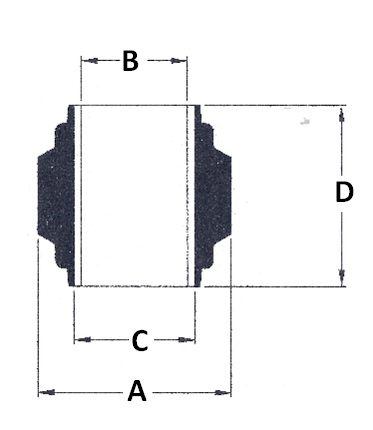

K22 Series Vibro-Insulators® Center Bonded Bushings

The K22 and K222 are one piece center bonded bushings that are designed to be compressed and fitted into a socket with a 2.22" diameter and a 1.88" length. The radial load deflections specified were tested in this manner. The K22 Series Bushings provide rotational freedom while utilizing a soft torsional spring rate.

Features and Benefits:

- Low Cost

- Easy to install

- Minimual maintenance

- Available in 2 sizes K22 (small) K222 (large)

- Produced with high strength Natural Rubber

- Available in 40, 50, 60, 70, and 80 Durometer Shore A

- Other elastomers available

- Metals are protected with zinc phosphate

- 2-D PDF prints are available for each mount

- 2-D DWG, 3-D IGES, and 3-D SolidWorks are available upon request

- Made in the USA

Applications:

Typical applications include: wheels, vibratory feeders, construction equipment, farm equipment, machinery

- All static load test data for the K22 Series Center Bonded Socket Style Vibro-Insulator® Mounts is based on Natural Rubber.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone, and sunlight.

Natural Rubber (NR):

All static load test data for the Center Bonded Socket Style Vibro-Insulator® Mounts is based on Natural Rubber.

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

- Cylindrical style mounts are not recomened in tension applications.

Neoprene (CR):

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N):

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 8 weeks.

1.37 |

.635/.645 |

.87 |

1.62 |

11500 |

.025 |

280 |

40 |

Natural Rubber |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

11500 |

.025 |

280 |

40 |

Neoprene |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

15100 |

.025 |

380 |

50 |

Natural Rubber |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

15100 |

.025 |

380 |

50 |

Neoprene |

|||

1.37 |

/includes/uploads/productFiles/K225.PDF |

.87 |

1.62 |

15100 |

.025 |

380 |

50 |

Nitrile |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

21000 |

.025 |

520 |

60 |

Natural Rubber |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

21000 |

.025 |

520 |

60 |

Neoprene |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

21000 |

.025 |

520 |

60 |

Nitrile |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

24800 |

.025 |

620 |

70 |

Natural Rubber |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

24800 |

.025 |

620 |

70 |

Neoprene |

|||

1.37 |

.635/.645 |

.87 |

1.62 |

24800 |

.025 |

620 |

70 |

Nitrile |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

12000 |

.04 |

480 |

40 |

Natural Rubber |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

12000 |

.04 |

480 |

40 |

Neoprene |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

16000 |

.04 |

640 |

50 |

Natural Rubber |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

16000 |

.04 |

640 |

50 |

Neoprene |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

16000 |

.04 |

640 |

50 |

Nitrile |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

21000 |

.04 |

840 |

60 |

Natural Rubber |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

21000 |

.04 |

840 |

60 |

Neoprene |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

21000 |

.04 |

840 |

60 |

Nitrile |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

26000 |

.04 |

1040 |

70 |

Natural Rubber |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

26000 |

.04 |

1040 |

70 |

Neoprene |

|||

2.39 |

1.318/1.324 |

1.50 |

2.24 |

26000 |

.04 |

1040 |

70 |

Nitrile |

|||

| Diameter - in (A) | Diameter - in (B) | Diameter - in (C) | Height - in (D) | Radial Spring Rate - lb/in | Radial Maximum Recommended Deflection - in | Radial Load at Maximum Deflection - lb | Shore A Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.