KS Series 304 Stainless Steel Vibro-Insulators® Male-Male

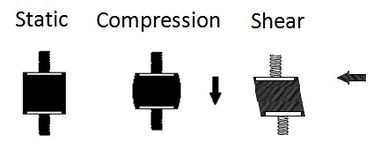

The KS Series 304 Stainless Steel Mounts are made of a high strength 50 Durometer Shore A Natural Rubber compound. Engineered and designed to have an excellent chemical and mechanical bond. The mounts are best used for compression loads with shear tendencies. The mounts are ideal for use in marine environments and equipment that is frequently cleaned with strong chemical agents. KS Series mount are not designed to be used in tension applications.

Features and Benefits:

- Low cost

- Easy instillation and no maintenance

- Excellent chemical and mechanical bond

- Excellent resistance to corrosion and harsh environments

- Resistant to oxidation

- Easy to clean

- Available in 3 styles and 7 sizes

- Available with 8-32 to 1/2-13 English and M4X0.7 to M12X1.75 Metric threads

- Compression loads ranging from 20 to 370 pounds

- Also available in Neoprene

- Made in the USA

General Applications:

- chemical plants, dairy, marine, food processing, hygienic, medical, packaging and environmental

Specific Applications:

- scales, weighing machines, fire trucks, medical apparatus, pumps, centrifuges, generators, compressors, modular and hard wall clean rooms, load cells, conveyors, HVAC equipment.

Environmental Data:

Natural Rubber (NR):

All static load test data for the Cylindrical 304 Stainless Steel Vibro-Insulator® Mounts is based on Natural Rubber.

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

- KS Series Stainless Steel Mounts are not recommended for tension loads.

Neoprene (CR):

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Source: American Chemical Society

Delivery is 8 weeks.

1.25 |

1.32 |

5/16-18 |

.625 |

.625 |

575 |

.125 |

70 |

80 |

.12 |

10 |

50 |

Natural Rubber |

2.25 |

||

1.25 |

1.32 |

5/16-18 |

.625 |

.625 |

575 |

.125 |

70 |

80 |

.12 |

10 |

50 |

Neoprene |

2.25 |

||

1.25 |

1.32 |

M8X1.25 |

.625 |

.625 |

575 |

.125 |

70 |

80 |

.12 |

10 |

50 |

Natural Rubber |

2.25 |

||

1.25 |

1.32 |

M8X1.25 |

.625 |

.625 |

575 |

.125 |

70 |

80 |

.12 |

10 |

50 |

Neoprene |

2.25 |

||

1.56 |

1.00 |

3/8-16 |

.625 |

.625 |

1250 |

.10 |

125 |

145 |

.15 |

20 |

50 |

Natural Rubber |

2.8 |

||

1.56 |

1.00 |

3/8-16 |

.625 |

.625 |

1250 |

.10 |

125 |

145 |

.15 |

20 |

70 |

Neoprene |

2.8 |

||

1.56 |

1.00 |

M10X1.50 |

.625 |

.625 |

1250 |

.10 |

125 |

145 |

.15 |

20 |

50 |

Natural Rubber |

2.8 |

||

1.56 |

1.00 |

M10X1.50 |

.625 |

.625 |

1250 |

.10 |

125 |

145 |

.15 |

20 |

50 |

Neoprene |

2.8 |

||

1.375 |

1.00 |

5/16-18 |

.625 |

.625 |

800 |

.10 |

80 |

105 |

.14 |

15 |

50 |

Natural Rubber |

1.92 |

||

1.375 |

1.00 |

5/16-18 |

.625 |

.625 |

800 |

.10 |

80 |

105 |

.14 |

15 |

50 |

Neoprene |

1.92 |

||

1.375 |

1.00 |

M8X1.25 |

.625 |

.625 |

800 |

.10 |

80 |

105 |

.14 |

15 |

50 |

Natural Rubber |

1.92 |

||

1.375 |

1.00 |

M8X1.25 |

.625 |

.625 |

800 |

.10 |

80 |

105 |

.14 |

15 |

50 |

Neoprene |

1.92 |

||

1.00 |

1.00 |

5/16-18 |

.625 |

.625 |

450 |

.10 |

45 |

80 |

.10 |

8 |

50 |

Natural Rubber |

1.3 |

||

1.00 |

1.00 |

5/16-18 |

.625 |

.625 |

450 |

.10 |

45 |

80 |

.10 |

8 |

50 |

Neoprene |

1.3 |

||

1.00 |

1.00 |

M8X1.25 |

.625 |

.625 |

450 |

.10 |

45 |

80 |

.10 |

8 |

50 |

Natural Rubber |

1.3 |

||

1.00 |

1.00 |

M8X1.25 |

.625 |

.625 |

450 |

.10 |

45 |

80 |

.10 |

8 |

50 |

Neoprene |

1.3 |

||

1.00 |

.75 |

1/4-20 |

.50 |

.50 |

675 |

.075 |

50 |

90 |

.10 |

9 |

50 |

Natural Rubber |

0.9 |

||

1.00 |

.75 |

1/4-20 |

.50 |

.50 |

675 |

.075 |

50 |

90 |

.10 |

9 |

50 |

Neoprene |

0.9 |

||

1.00 |

.75 |

M6X1.0 |

.50 |

.50 |

675 |

.075 |

50 |

90 |

.10 |

9 |

50 |

Natural Rubber |

.9 |

||

1.00 |

.75 |

M6X1.0 |

.50 |

.50 |

675 |

.075 |

50 |

90 |

.10 |

9 |

50 |

Neoprene |

.9 |

||

3.12 |

1.50 |

1/2-13 |

1.25 |

1.25 |

4275 |

.15 |

668 |

572 |

.314 |

199 |

50 |

Natural Rubber |

20 |

||

3.12 |

2.25 |

1/2-13 |

1.25 |

1.25 |

1800 |

.40 |

720 |

480 |

.30 |

140 |

50 |

Natural Rubber |

24 |

||

2.00 |

.75 |

3/8-16 |

1.12 |

1.12 |

5000 |

.075 |

370 |

600 |

.15 |

90 |

50 |

Natural Rubber |

3.85 |

||

2.00 |

.75 |

3/8-16 |

1.12 |

1.12 |

5000 |

.075 |

370 |

600 |

.15 |

90 |

50 |

Neoprene |

3.85 |

||

2.00 |

.75 |

M10X1.50 |

1.12 |

1.12 |

5000 |

.075 |

370 |

600 |

.15 |

90 |

50 |

Natural Rubber |

3.85 |

||

2.00 |

.75 |

M10X1.50 |

1.12 |

1.12 |

5000 |

.075 |

370 |

600 |

.15 |

90 |

50 |

Neoprene |

3.85 |

||

.625 |

.50 |

8-32 |

.50 |

.50 |

400 |

.05 |

20 |

50 |

.06 |

3 |

50 |

Natural Rubber |

0.3 |

||

.625 |

.50 |

8-32 |

.50 |

.50 |

400 |

.05 |

20 |

50 |

.06 |

3 |

50 |

Neoprene |

0.3 |

||

.625 |

.50 |

M4X0.7 |

.50 |

.50 |

400 |

.05 |

20 |

50 |

.06 |

3 |

50 |

Natural Rubber |

.03 |

||

.625 |

.520 |

M4X0.7 |

.550 |

.550 |

400 |

.05 |

20 |

50 |

.06 |

3 |

50 |

Neoprene |

.03 |

||

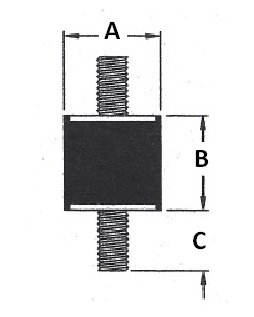

| Diameter - in (A) | Rubber Height - in (B) | Thread Size | Thread Length - in (C) | Thread Length - in (D) | Compression Spring Rate - lb/in | Compression Maximum Recommended Deflection - in | Compression Load at Maximum Deflection - lb | Shear Spring Rate - lb/in | Shear Maximum Recommended Deflection - in | Shear Load at Maximum Deflection - lb | Durometer | Elastomer | Part Weight - oz |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.