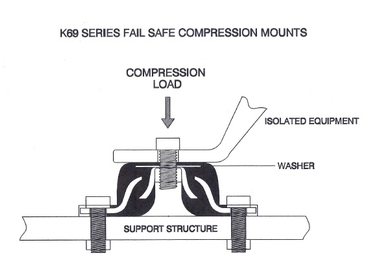

K69 Series Vibro-Insulator® Fail-Safe Compression Mounts

Karman Rubber offers the largest selection of compression style fail-safe designed mounts available anywhere. With compressive loads starting at just 46 pounds (20 kg) the patent pending K692 Vibro-Isolator® is the smallest compression style fail-safe designed flange mount in the world. Totally encapsulated in the Neoprene elastomer the K692, K635, K696, K697, K698, and K699 mounts are ideally suited toward harsh marine environments or constant wash down applications.

K69 Series Features and Benefits:

- Low Cost

- One-piece construction

- Easy of installation with no maintenance

- Encapsulated in Neoprene for use in marine, food processing, chemical, and outdoor applications

- Also available in Natural Rubber and Nitrile (Buna-N)

- Bottom mounting surfaces are ribbed for improved grip

- Rated for higher loads due to the interlocking metal design

- Seismic rating of 1g (acceleration of gravity)

- Seismic protection in earthquake zones. See below for g-force ratings

- Available in English (1/4-20 to 3/4-10) and Metric (M6X1.0 to M20X2.5) hardware

- Six sizes with 5 load ranges for each size

- Available in 30, 40, 50, 60, and 70 Durometer Shore A

- Load ranges from 46 to 8400 pounds of static compressive loads

- Fail-safe patented designs with interlocking metals

- No need for snubbing washers

- Excellent performance with one, two, three, four and five cylinder engines

- High and Low frequency applications

- All directional mounts can be used in shear, tension, and compression applications

- Suited for low mounting applications

- Made in the USA

K69 Series Applications:

- Motors, generators, and compressors

- HVAC equipment

- Chemical and food processing equipment

- Centrifuges and pumps

- Highway and off-highway machinery

- Trucks, buses, lifts, and rail transportation

- Marine equipment and ATV's

- Fans blowers and portable power equipment

- Seismic protection in earthquake zones

K69 Series Material and Environmental Data:

- Neoprene elastomer available in 30, 40, 50, 60, & 70 Durometer Shore A.

- Operating temperature range (10° F to 180° F).

- Ozone resistant.

- Oil, gasoline, and solvent resistant.

- Flame resistant

- Structure made. of corrosion resistant carbon steel.

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Neoprene (CR)

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N)

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 6 weeks.

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

1200 |

.08 |

85 |

30 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

2200 |

0.08 |

170 |

40 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

2200 |

0.08 |

170 |

40 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Nitrile |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Nitrile |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

5/16-18 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Nitrile |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

1200 |

0.08 |

85 |

30 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

2200 |

0.08 |

170 |

40 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

2200 |

0.08 |

170 |

40 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

3100 |

0.08 |

250 |

50 |

Nitrile |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

4300 |

0.08 |

340 |

60 |

Nitrile |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Natural Rubber |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Neoprene |

2.7 |

|||

1.5 |

1.2 |

2.375 |

3.13 |

M8X1.25 |

1.73 |

1.02 |

0.07 |

0.19 |

0 |

0.34 |

8500 |

0.08 |

650 |

70 |

Nitrile |

2.7 |

|||

1.13 |

.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

879 |

0.052 |

46 |

30 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

1687 |

0.052 |

87 |

40 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

1687 |

0.052 |

87 |

40 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Nitrile |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Nitrile |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

1/4-20 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Nitrile |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

879 |

0.052 |

46 |

30 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

1687 |

0.052 |

87 |

40 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

1687 |

0.052 |

87 |

40 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2230 |

0.052 |

115 |

50 |

Nitrile |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

2643 |

0.052 |

137 |

60 |

Nitrile |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Natural Rubber |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Neoprene |

0.95 |

|||

1.13 |

0.92 |

1.75 |

2.27 |

M6X1.0 |

1.25 |

0.75 |

0.05 |

0.14 |

0 |

0.26 |

3441 |

0.052 |

179 |

70 |

Nitrile |

0.95 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

2100 |

0.1 |

210 |

30 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

3700 |

0.1 |

340 |

40 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

3700 |

0.1 |

340 |

40 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Nitrile |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Nitrile |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

9400 |

8 |

750 |

70 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

9400 |

8 |

750 |

70 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

3/8-16 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

9400 |

8 |

750 |

70 |

Nitrile |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

2100 |

0.1 |

210 |

30 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

3700 |

0.1 |

340 |

40 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

3700 |

0.1 |

340 |

40 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

5200 |

0.1 |

520 |

50 |

Nitrile |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

6800 |

0.1 |

680 |

60 |

Nitrile |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

8400 |

0.08 |

750 |

70 |

Natural Rubber |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

8400 |

0.08 |

750 |

70 |

Neoprene |

6.5 |

|||

2.15 |

1.86 |

3 |

3.81 |

M8X1.25 |

2.32 |

1.25 |

0.12 |

0.24 |

0.065 |

0.34 |

8400 |

0.08 |

750 |

70 |

Nitrile |

6.5 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

13375 |

0.17 |

2270 |

30 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

20750 |

0.17 |

3520 |

40 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

20750 |

0.17 |

3520 |

40 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

4124 |

50 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

4124 |

50 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

4124 |

50 |

Nitrile |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

6600 |

60 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

6600 |

60 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

6600 |

60 |

Nitrile |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

8400 |

70 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

8400 |

70 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

3/4-10 HD |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

8400 |

70 |

Nitrile |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

13375 |

0.17 |

1735 |

30 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

20750 |

0.17 |

2630 |

40 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

20750 |

0.17 |

2630 |

40 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

3650 |

50 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

3650 |

50 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

24264 |

0.17 |

3650 |

50 |

Nitrile |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

5720 |

60 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

5720 |

60 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

39058 |

0.17 |

5720 |

60 |

Nitrile |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

7750 |

70 |

Natural Rubber |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

7750 |

70 |

Neoprene |

51 |

|||

4.93 |

4.12 |

6 |

7.41 |

M20X2.5 |

5.1 |

2.25 |

0.156 |

0.27 |

0.12 |

0.63 |

49509 |

0.17 |

7750 |

70 |

Nitrile |

51 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

3800 |

0.125 |

471 |

30 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

5800 |

0.125 |

713 |

40 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

5800 |

0.125 |

713 |

40 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Nitrile |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Nitrile |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

13000 |

0.125 |

1600 |

70 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

1/2-13 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

13000 |

0.125 |

1600 |

70 |

Nitrile |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

3800 |

0.125 |

471 |

30 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

5800 |

0.125 |

713 |

40 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

5800 |

0.125 |

713 |

40 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

7500 |

0.125 |

940 |

50 |

Nitrile |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Natural Rubber |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

8650 |

0.125 |

1064 |

60 |

Nitrile |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

13000 |

0.125 |

1600 |

70 |

Neoprene |

17 |

|||

3.23 |

2.42 |

4.12 |

5.5 |

M12X1.75 |

3.37 |

1.78 |

0.12 |

0.24 |

0.12 |

0.51 |

13000 |

0.125 |

1600 |

70 |

Nitrile |

17 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

7577 |

0.125 |

900 |

30 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

9285 |

0.125 |

1106 |

40 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

9285 |

0.125 |

1106 |

40 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Nitrile |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

20119 |

0.125 |

2500 |

60 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

.12 |

.24 |

.12 |

.53 |

20119 |

.125 |

2500 |

60 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

20119 |

0.125 |

2500 |

60 |

Nitrile |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

3/4-10 HD |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Nitrile |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

7577 |

0.125 |

900 |

30 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

9285 |

0.125 |

1100 |

40 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

9285 |

0.125 |

1100 |

40 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

13071 |

0.125 |

1630 |

50 |

Nitrile |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

20119 |

0.125 |

2500 |

60 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

20119 |

0.125 |

2500 |

60 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

20119 |

0.125 |

2500 |

60 |

Nitrile |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Natural Rubber |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Neoprene |

29 |

|||

3.91 |

3.1 |

5 |

6.41 |

M20X2.5 |

4.09 |

1.84 |

0.12 |

0.24 |

0.12 |

0.53 |

34400 |

0.125 |

4300 |

70 |

Nitrile |

29 |

|||

| Mount Diameter - in (A) | Top Diameter - in (B) | Mounting Holes on Center - in (C) | Length - in (D) | Thread Tap or Hole Size (E) | Width - in (F) | Height - in (G) | Insert Thickness - in (H) | Flange Thickness - in (H2) | Washer Thickness - in (I) | Mounting Holes - in (J) | Spring Rate - lb/in | Maximum Recommended Deflection - in | Load at Maximum Deflection - lb | Durometer | Elastomer | Part Weight - oz | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.