Single Male Vibro-Isolator® Bumpers

Male conical bumpers and feet have a machined insert that is both chemically and mechanically bonded. These bumpers are highly durable at extreme temperatures. They can be used in thousands of applications.

Features and Benefits:

- Easy to install and little maintenance

- Low cost

- Excellent skid resitenance

- Highly durable

- 50 & 60 Durometer Shore A elastomers offer an excellent rebound

- Natural Rubber (-40° F to 155°F) and Nitrile (-40° F to 300° F) elastomers have excellent resistance to extreme tempatures

- 2-D PDF prints are available for each mount

- 2-D DWG, 3-D IGES, and 3-D SolidWorks are available upon request

- Made in the USA

Environmental Data:

- All static load test data for Bumpers and Feet Vibro-Isolator® Mounts is based on Natural Rubber.

- Natural Rubber operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasolene, ozone, and sunlight.

- Other elastomers such as Neoprene and Nitrile (Buna-N) are available upon request.

Natural Rubber (NR):

All static load test data for Bumpers and Feet Vibro-Isolators® Mounts is based on Natural Rubber.

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

Neoprene (CR):

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° to 180° F).

Nitrile (Buna-N):

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 8 weeks.

1.62 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

40 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

40 |

Neoprene |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

175 |

.33 |

55 |

50 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

175 |

.33 |

55 |

50 |

Neoprene |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

175 |

.33 |

55 |

50 |

Nitrile |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

60 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

60 |

Neoprene |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

60 |

Nitrile |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

70 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

70 |

Neoprene |

||||

1.625 |

1.75 |

3/8-24 |

.625 |

N/A |

N/A |

N/A |

70 |

Nitrile |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

40 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

40 |

Neoprene |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

175 |

.33 |

55 |

50 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

175 |

.33 |

55 |

50 |

Neoprene |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

175 |

.33 |

55 |

50 |

Nitrile |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

60 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

60 |

Neoprene |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

60 |

Natural Rubber |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

70 |

Neoprene |

||||

1.625 |

1.75 |

3/8-16 |

.625 |

N/A |

N/A |

N/A |

70 |

Nitrile |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

135 |

.60 |

74 |

40 |

Natural Rubber |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

135 |

.60 |

74 |

40 |

Neoprene |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

190 |

.60 |

115 |

50 |

Natural Rubber |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

190 |

.60 |

115 |

50 |

Neoprene |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

190 |

.60 |

115 |

50 |

Nitrile |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

270 |

.60 |

160 |

60 |

Natural Rubber |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

270 |

.60 |

160 |

60 |

Neoprene |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

270 |

.60 |

160 |

60 |

Nitrile |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

370 |

.60 |

220 |

70 |

Natural Rubber |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

370 |

.60 |

220 |

70 |

Neoprene |

||||

1.75 |

3.00 |

5/16-18 |

.625 |

370 |

.60 |

220 |

70 |

Nitrile |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

110 |

.60 |

65 |

40 |

Natural Rubber |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

110 |

.60 |

65 |

40 |

Neoprene |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

190 |

.60 |

115 |

50 |

Natural Rubber |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

190 |

.60 |

115 |

50 |

Neoprene |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

190 |

.60 |

115 |

50 |

Nitrile |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

270 |

.60 |

160 |

60 |

Natural Rubber |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

270 |

.60 |

160 |

60 |

Neoprene |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

270 |

.60 |

160 |

60 |

Nitrile |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

370 |

.60 |

220 |

70 |

Natural Rubber |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

370 |

.60 |

220 |

70 |

Neoprene |

||||

1.75 |

3.00 |

M8X1.25 |

.625 |

370 |

.60 |

220 |

70 |

Nitrile |

||||

1.00 |

.50 |

1/4-20 |

.50 |

500 |

.05 |

25 |

70 |

Natural Rubber |

||||

1.00 |

.50 |

1/4-20 |

.50 |

500 |

.05 |

25 |

50 |

Neoprene |

||||

1.00 |

.50 |

1/4-20 |

.50 |

500 |

.05 |

25 |

50 |

Nitrile |

||||

1.00 |

.50 |

M6X1 |

.50 |

500 |

.05 |

25 |

50 |

Natural Rubber |

||||

1.00 |

.50 |

M6X1 |

.50 |

500 |

.05 |

25 |

50 |

Neoprene |

||||

1.00 |

.50 |

M6X1 |

.50 |

500 |

.05 |

25 |

50 |

Nitrile |

||||

.94 |

.65 |

1/4-20 |

.50 |

170 |

.07 |

12 |

40 |

Natural Rubber |

||||

.94 |

.65 |

1/4-20 |

.50 |

170 |

.07 |

12 |

40 |

Neoprene |

||||

.94 |

.65 |

1/4-20 |

.50 |

250 |

.07 |

18 |

50 |

Natural Rubber |

||||

.94 |

.65 |

1/4-20 |

.50 |

250 |

.07 |

18 |

50 |

Neoprene |

||||

.94 |

.65 |

1/4-20 |

.50 |

250 |

.07 |

18 |

50 |

Nitrile |

||||

.94 |

.65 |

1/4-20 |

.50 |

340 |

.07 |

24 |

60 |

Natural Rubber |

||||

.94 |

.65 |

1/4-20 |

.50 |

340 |

.07 |

24 |

60 |

Neoprene |

||||

.94 |

.65 |

1/4-20 |

.50 |

340 |

.07 |

24 |

60 |

Nitrile |

||||

.94 |

.65 |

1/4-20 |

.50 |

500 |

.07 |

35 |

70 |

Natural Rubber |

||||

.94 |

.65 |

1/4-20 |

.50 |

500 |

.07 |

35 |

70 |

Neoprene |

||||

.94 |

.65 |

1/4-20 |

.50 |

500 |

.07 |

35 |

70 |

Nitrile |

||||

.94 |

.65 |

M6X1 |

.50 |

170 |

.07 |

12 |

40 |

Natural Rubber |

||||

.94 |

.65 |

M6X1 |

.50 |

170 |

.07 |

12 |

40 |

Neoprene |

||||

.94 |

.65 |

M6X1 |

.50 |

250 |

.07 |

18 |

50 |

Natural Rubber |

||||

.94 |

.65 |

M6X1 |

.50 |

250 |

.07 |

18 |

50 |

Neoprene |

||||

.94 |

.65 |

M6X1 |

.50 |

250 |

.07 |

18 |

50 |

Nitrile |

||||

.94 |

.65 |

M6X1 |

.50 |

340 |

.07 |

24 |

60 |

Natural Rubber |

||||

.94 |

.65 |

M6X1 |

.50 |

340 |

.07 |

24 |

60 |

Neoprene |

||||

.94 |

.65 |

M6X1 |

.50 |

340 |

.07 |

24 |

60 |

Nitrile |

||||

.94 |

.65 |

M6X1 |

.50 |

500 |

.07 |

35 |

70 |

Natural Rubber |

||||

.94 |

.65 |

M6X1 |

.50 |

500 |

.07 |

35 |

70 |

Neoprene |

||||

.94 |

.65 |

M6X1 |

.50 |

500 |

.07 |

35 |

70 |

Nitrile |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

625 |

.38 |

230 |

40 |

Natural Rubber |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

625 |

.38 |

230 |

40 |

Neoprene |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1100 |

.38 |

410 |

50 |

Natural Rubber |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1100 |

.38 |

410 |

50 |

Neoprene |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1100 |

.38 |

4.10 |

50 |

Nitrile |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1800 |

.38 |

675 |

60 |

Natural Rubber |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1800 |

.38 |

675 |

60 |

Neoprene |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

1800 |

.38 |

675 |

60 |

Nitrile |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

2900 |

.38 |

1100 |

70 |

Natural Rubber |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

2900 |

.38 |

1100 |

70 |

Neoprene |

||||

3.175 |

2.50 |

M12X1.75 |

1.25 |

2900 |

.38 |

1100 |

70 |

Nitrile |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

625 |

.38 |

230 |

40 |

Natural Rubber |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

625 |

.38 |

230 |

40 |

Neoprene |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1100 |

.38 |

410 |

50 |

Natural Rubber |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1100 |

.38 |

410 |

50 |

Neoprene |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1100 |

.38 |

410 |

50 |

Nitrile |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1800 |

.38 |

675 |

60 |

Natural Rubber |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1800 |

.38 |

675 |

60 |

Neoprene |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

1800 |

.38 |

675 |

60 |

Nitrile |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

2900 |

.38 |

1100 |

70 |

Natural Rubber |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

2900 |

.38 |

1100 |

70 |

Neoprene |

||||

3.175 |

2.50 |

1/2-13 |

1.25 |

2900 |

.38 |

1100 |

70 |

Nitrile |

||||

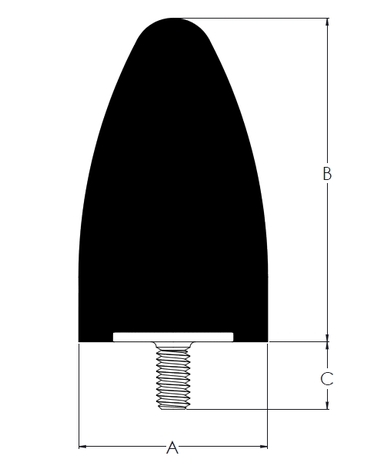

| Diameter - in (A) | Height - in (B) | Thread Size | Thread Length - in (C) | Compression Spring Rate - lb/in | Compression Maximum Recommended Deflection - in | Compression Load at Maximum Deflection - lb | Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.