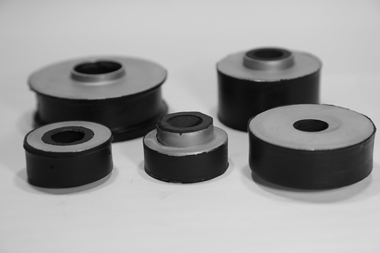

K50 Series Torsional Vibro-Insulators®

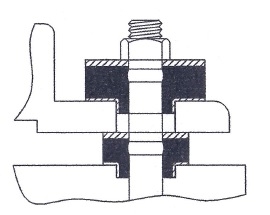

The K591, K55, and K555 Dount Style Vibro-Insulators® are designed to be used in applications where one mount is required, or in conjunction with other mounts that are in this series. The mounts will protect light to medium weight equipment from structure borne noise and vibration. They will also dampen low frequency vibrations from outside sources. The rebound mount is used to limit movement from low frequency vibration and shock. These mounts may also be used in series with the K50's.

These mounts are also refered to as torsional mounts, ring mounts and donut mounts, machinery mounts and rebounds.

Features and Benefits:

- Low cost

- Easy to install and minimal maintenance

- Available in Natural Rubber, Neoprene, and Nitrile (Buna-N)

- Available in 30, 40, 50, 60, and 70 Durometer Shore A

- Compression load raning from 100 to 870 pounds (45 to 394 kilograms)

- 2-D PDF prints are available for each mount

- 2-D DWG, 3-D IGES, and 3-D SolidWorks are available upon request

- Made in the USA

Applications:

- Motors, blowers, fans, radiators, cabs, gensets, engine mounts,

- Military, transporation, HVAC, rail, construction, off highway

Environmental Data:

- All static load test data for the Torsional Vibro-Insulator® Mounts is based on Neoprene.

- Operating temperatures should not exceed 180° F.

- Other elastomers such as Natural Rubber and Nitrile (Buna-N) are available upon request.

Natural Rubber (NR)

Advantages: Outstanding resilience; high tensile strength; superior resistance to tear and abasion; excellent rebound elasticity (snap); good flexibility at low temperatures (-40° F to 155° F).

Limitations: Poor resistance to heat, ozone, and sunlight; very little resistance to oil gasoline, and hydrocarbon solvents.

- Operating temperatures should not exceed 155° F.

- Natural Rubber is not recommended from exposure to oil, gasoline, ozone sunlight.

- Cylindrical style mounts are not recomened in tension applications.

Neoprene (CR)

All static load test data for the Torsional Vibro-Insulator® Mounts is based on Neoprene.

Advantages: Good inherent flame resistance; moderate resistance to oil and gasoline; very good resistance to weather, ozone, and natural aging; good resistance to flex cracking; very good resistance to alkalis and acids.

Limitations: Poor to fair resistance aromatic and oxygenated solvents; limited flexibility at low temperatures (10° F to 180° F).

Nitrile (Buna-N)

Advantages: Very good resistance to oil and gasoline; superior resistance to petroleum-based hydraulic fluids; wide range of service temperatures (-65° F to 300° F); good resistance to hydrocarbon solvents; very good resistance to alkalis and acids.

Limitations: Inferior resistance to ozone, sunlight, and natural aging; poor resistance to oxygenated solvents.

Source: American Chemical Society

Delivery is 8 weeks.

2.27 |

1.12 |

.635 |

.79 |

.234 |

2700 |

.05 |

130 |

40 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

2700 |

.05 |

130 |

40 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

3800 |

.05 |

190 |

50 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

3800 |

.05 |

190 |

50 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

3800 |

.05 |

190 |

50 |

Nitrile |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

4700 |

.05 |

230 |

60 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

4700 |

.05 |

230 |

60 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

4700 |

.05 |

230 |

60 |

Nitrile |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

7500 |

.05 |

370 |

70 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

7500 |

.05 |

370 |

70 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

.79 |

.234 |

7500 |

.05 |

370 |

70 |

Nitrile |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

1200 |

.16 |

190 |

40 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

1200 |

.16 |

190 |

40 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

1700 |

.16 |

270 |

50 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

1700 |

.16 |

270 |

50 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

1700 |

.16 |

270 |

50 |

Nitrile |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

2300 |

.16 |

370 |

60 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

2300 |

.16 |

370 |

60 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

2300 |

.16 |

370 |

60 |

Nitrile |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

3300 |

.16 |

530 |

70 |

Natural Rubber |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

3300 |

.16 |

530 |

70 |

Neoprene |

|||

2.27 |

1.12 |

.635 |

1.22 |

.234 |

3300 |

.16 |

530 |

70 |

Nitrile |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

1050 |

.10 |

105 |

40 |

Natural Rubber |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

1050 |

.10 |

105 |

40 |

Neoprene |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

1500 |

.10 |

150 |

50 |

Natural Rubber |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

1500 |

.10 |

150 |

50 |

Neoprene |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

1500 |

.10 |

150 |

50 |

Nitrile |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

2000 |

.10 |

200 |

60 |

Natural Rubber |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

2000 |

.10 |

200 |

60 |

Neoprene |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

2000 |

.10 |

200 |

60 |

Nitrile |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

3200 |

.10 |

320 |

70 |

Natural Rubber |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

3200 |

.10 |

320 |

70 |

Neoprene |

|||

1.63 |

1.12 |

.625 |

.68 |

.13 |

3200 |

.10 |

320 |

70 |

Nitrile |

|||

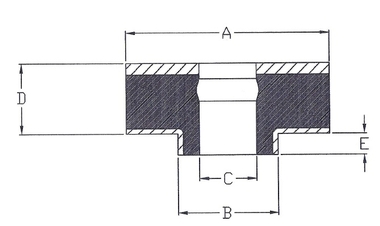

| Diameter - in (A) | Diameter - in (B) | Diameter - in (C) | Height - in (D) | Step - in (E) | Compression Spring Rate - lb/in | Compression Maximum Recommended Deflection - in | Compression Load at Maximum Deflection - lb | Durometer | Elastomer | Dimensional CAD Drawing (pdf) |

Use the sort keys located at the bottom of the table to find the exact Vibro-Insulator© you require. Please contact us for selection help.